Top search terms

Haven’t you figured out how Chengdu Krah pipes are manufactured?

2025-01-09

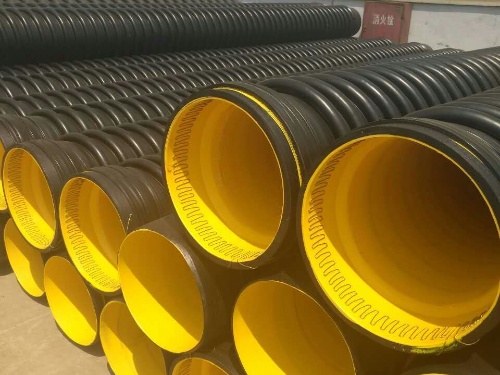

The manufacturing process of Chengdu Krah pipes mainly includes the following steps:

- Equipment Heating: Heat the steel roller moulds used for Krah pipe production.

- Winding: Adopt the hot state winding forming process to wind the molten HDPE flat strips and PP - coated circular ribs onto the steel moulds.

- Cutting: Machine the spigot and socket ends of the pipes to standard dimensions.

- Demoulding: Remove the pipes from the moulds.

- Trimming: Smooth and standardize the appearance of the pipes.

- Electrofusion Wire Embedding: Pre - embed electrofusion wires inside the socket walls of the pipes.

- Product Inspection: Inspect the appearance and dimensions of the products to ensure only qualified products leave the factory.

Material and Process Characteristics of Krah Pipes

Krah pipes are made from high - density polyethylene (HDPE) resin, with PP or PE corrugated pipes as auxiliary support pipes, and produced via the hot winding forming process. This process endows Krah pipes with the advantages of light weight, high pressure resistance, excellent joint quality, long service life, corrosion resistance, high ring stiffness and convenient construction.